Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible

Supply chain management handles the capacity and capability to deliver products or services on time, with quality, and within budget. It encompasses engineering, procurement, planning, manufacturing, warehouse, and project management activities. Supply chain management is filled with ever-changing obstacles like raw material shortages, new product development, and on-time delivery for companies during normal operational conditions. It’s a continuous project in the global delivery process for today’s companies.

The client, a leading international aerospace supplier for commercial aircrafts, faced difficulties with its suppliers after a fast transfer of work and needed help to reduce its backlog and improve its supply chain performance.

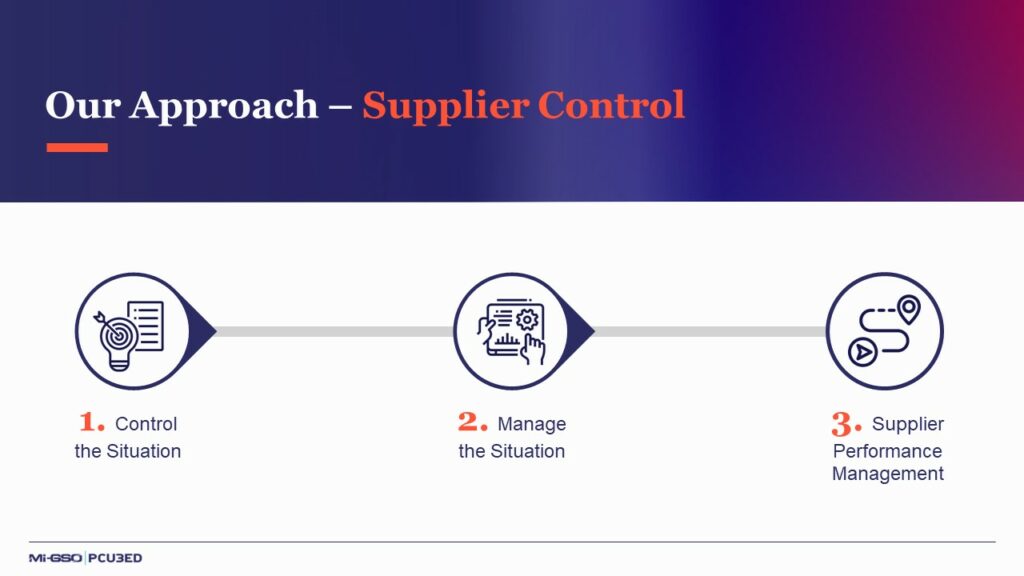

MIGSO-PCUBED was brought on board to help maintain the relationship between the client and their manufacturing suppliers. The consultant’s team did this by first working on communication and repairing the relationship between the client and stakeholders. At the same time, they implemented a successful recovery plan for the manufacturer’s backlog and a continuous improvement plan to avoid another potential crisis. MP also created a supply chain data tracking process, collected, charted, and implemented a daily routine with both the client and the stakeholders.

During the peak of the epidemic, companies had to adapt to our new and changing world. The aerospace industry was profoundly affected and had to condense its assets. As a result, in early 2022 the client needed to shut down a manufacturing facility rapidly and found themselves scrambling to replace this loss. Multiple suppliers were recruited on short notice, so the procurement and supplier quality management (SQM) team needed to choose an appropriate new supplier and validate their planned delivery capacity.

This new supplier inherited the bulk of the transition. They were dealing with issues related to the abrupt relocation caused by the closure. The manufacturing company was very guarded, restricting the visibility of internal operations. They were also understaffed and overwhelmed by the client’s needs. Without proper visibility and communication, our client was unable to get an accurate plan for the production needed to fulfill their customer’s demands.

This was the perfect storm of miscommunication and frustration. MIGSO-PCUBED was recruited to maintain the relationship between our client and a new manufacturing supplier as an onsite supply chain project manager.

Amidst the abrupt transition, deadlines were looming and both entities became stalled while trying to find a quick way to implement new and effective supply chain processes. Before addressing and executing the supply chain recovery plan, it was important to first unify the teams and improve their communications. MP became the mediator between the client and the manufacturer.

The first step was to listen and rebuild trust between all parties involved. By relating as an individual to both the client and the manufacturer’s key personnel, both parties opened up so MP could better understand what each party needed. It was important to make all involved feel we were all part of the same team working towards a common goal. Once the philosophy took hold the client and the manufacturer began to operate as a team.

Once teams across the organizations became established, MP had to bridge the gaps in communication that led to supply chain delays. The MP onsite consultant established a working relationship with all of the clients’ many facilities and entities by becoming the point of contact for the manufacturer.

MP tracked any production and delivery issues and kept them highly visible for all parties involved with daily cadences and open discussions. The MP consultant filled a critical role that had previously been unavailable, acting as both a liaison for the client and a stand-in for the manufacturer.

Once the teams were clearly defined and a working communications plan was in place, the MP team shifted its focus to identifying, tracking, and solving issues within the supply chain.

MP tracked the manufacturer’s production data and provided daily Excel-based reports and charts to track progress. With the new data, the manufacturer and client acknowledged the benefits; now, both parties can accurately estimate production numbers and timelines.

The new data provided clarity for the client to properly forecast production. This allowed them to complete the recovery of output that was behind from the loss of their manufacturing facility and the learning curve of the transition to the manufacturers in early 2022.

MP helped the client determine the need to move 35% of the scheduled production work from the manufacturer to other vendors to meet their clients’ needs. MP handled the transfer of work, which included the transfer of tools to the new sites and the repositioning of purchase orders to align with the move.

The consultant worked with the client to determine which family of parts could be moved with the least amount of disruption to the business. MP then collaborated with the manufacturer’s shipping department to collect, palletize, ship, and track the distribution of all necessary tools.

The data also provided MP with clarity to identify an opportunity that was missed in the manufacturer’s Material Requirements Planning (MRP) system. The team was able to alter production methods to include a more efficient pre-planning process that was also incorporated into the MRP system. The manufacturer reworked the production recovery project to achieve a reachable goal of concluding in sixty days.

MP was able to both solve the immediate business need of the client to recover their production, and to provide a formula for success that both companies can cascade through their business. All entities are now equipped with a team-building perspective, an effective communication plan with transparency of obstacles and expectations, and best practices for data collection.

The recovery plan that MP implemented was a success. The initial challenges that the client faced are now under control after four months, and the relationship with three of their suppliers has drastically improved.

The manufacturer has adopted the MP production recovery project as a standard practice which is helping their production efficiency by at least 200%. The client could begin its exit strategy from onsite recovery management to normal operations between the client and its suppliers and also improve the organization’s overall project management maturity.

The client’s supply chain no longer sees any disruption since MP arrived. Now, even in the event of a crisis, they know how to manage it quickly with MP as their partner. Furthermore, the client plans to continue collaborating with MP to support their improvement projects.

This article was written by Aric Morley.

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.

We combine our expertise with a fine knowledge of the industry to deliver high-value project management services.

MIGSO-PCUBED is part of the ALTEN group.

Find us around the world

Australia – Canada – France – Germany – Italy – Mexico – Portugal – Romania – South East Asia – Spain – Switzerland – United Kingdom – United States

© 2024 MIGSO-PCUBED. All rights reserved | Legal information | Privacy Policy | Cookie Settings | Intranet

Choose your language

Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible