Project Controls, Driving Success for a Luxury Car Manufacturer

- Automotive & Transportation, PMO & Project Delivery

This project was a finalist at the Association for Project Management’s annual awards ceremony.

The automotive industry is undergoing a substantial transformation. Factors such as the rollout of low-emission technology, Advanced Driver Assistance Systems (ADAS), connectivity features, and the shift from analogue to more digital and connected vehicles have contributed to increased complexity across the full lifecycle of a vehicle programme.

Furthermore, market pressures have shortened the lifecycle of a vehicle. At the turn of the century a vehicle model would typically be in production for roughly 7 to 9 years whereas now they are only produced for 4 to 6 years before a replacement model comes along.

This puts further pressure on car companies and their supply chains as despite efficiency gains from technologies like Computer-Aided Design (CAD), increased platform sharing, and collaboration between marques, the industry needs to essentially deliver a more complex vehicle in a shorter time with a leaner workforce and tighter budgets.

Consequently, there’s a heightened recognition of the need for structured and professionalised project management within the automotive sector. Traditionally viewed as a side task for engineers, project management is becoming increasingly acknowledged by senior industry executives as a specialised discipline requiring dedicated learning and development pathways, with many car companies investing in project management capabilities to make it easier for engineering teams to navigate what are unbelievably complex products.

This investment can take the form of strategic partnerships with external providers or internal initiatives focused on enhancing project management skills, training, and career paths and typically deliver loss avoidances within the millions due to having increased predictability and visibility of risks, issues and opportunities.

Within the development process, one area which can often highlight issues within a vehicle development programme is the prototyping function. This is because prototyping forms a crucial bridge between conceptual design, engineering, and mass production.

As a result, technical challenges or integration issues that may have otherwise been missed because of inefficient project control often first become apparent, meaning that the function is equipped to act as a control tower relaying information back into the core programme teams.

Table of Contents

Product Delivery Challenges

In this example, our client is a leading luxury OEM who are part of one of the world’s largest automotive groups, and their prototyping function was experiencing many of the challenges detailed above.

The result of this, despite a business need to release multiple new models in less than 10 years, was that all programmes were delayed and were likely to miss their starts of production, which could have resulted in a ten-figure revenue impact to the business as they essentially would have not had a product to sell that was relevant to the consumer and compliant with new legislation.

These issues were intensified by a lack of project management control within the prototyping function itself, which made it hard for the client to:

- Understand impact before making decisions;

- Have an understanding of ‘where we are and why’ within day-to-day delivery;

- Consistently plan using standardised tools / templates and accepted logic.

As a result of this, our client opted to leverage our expertise and long-term trusted relationship within their group to help improve project management maturity within the prototyping team and in parallel get multiple business critical programmes back on track.

Framing the Challenge

To achieve the rate of change needed by the customer team, we worked together to structure a transformation project around five main workstreams:

- Operational Support: providing surge capacity and extra horsepower to help the customer team to continue progressing their vehicle programmes and give them capacity as individuals to support the transformation.

- Ways of working: design and implementation of new / updated tools, templates and processes to ensure the team had better visibility of what was happening day to day with the ability to model impact of changes through ‘what if’ analysis.

- PM Capability: enhancement of the project delivery team’s project management capability in line with the Association for Project Management’s competency framework

- Team Culture: cultivate collaboration to facilitate accelerated problem solving and a business improvement centric culture of change.

- Governance: standardised metrics, artefacts, reports, and meeting cadence.

Our adaptive delivery approach also ensured innovative ideas were encouraged and prioritised through a weekly continuous improvement forum which was attended by the full client team. In these sessions, opportunities were highlighted using a Lean A3 problem-solving approach. We tracked leading indicators on a KPI dashboard which helped ensure alignment with the desired outcomes, as validated by the lagging measure of on-time-In-full delivery.

Our Three Step Delivery Approach

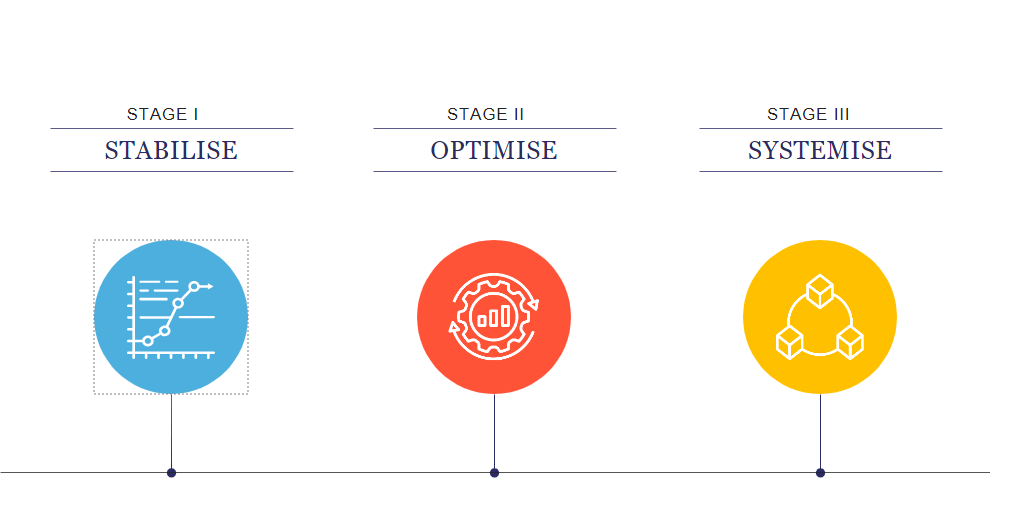

Leveraging our adaptive delivery methodology, when it comes to structure, the project itself was split across three key stages in a waterfall manner, with agile day-to-day working within each of the workstreams to enable better responsiveness to change.

Stage 1- Stabilise: Identify the critical customer pain points and deliver rapid solutions to stabilise performance.

Here, pain points and risks and issues within vehicle programmes were rapidly identified. A KPI dashboard and Kanban board were implemented to track opportunities to deliver quick wins and with a cross-functional team to aid management dependencies. These were managed through a daily and weekly meeting cadence, and 20 processes were documented with process maps, task descriptions and guidance. This stabilised and improved right-first-time operational delivery performance to 99% right first-time against 80% target.

Stage 2- Optimise: Bring the people who do the job together, develop and test solutions to optimise ways of working.

8 workstreams were identified to optimise project delivery performance, leveraging the benefits of inclusivity, diversity of thought, perspectives, and experience within the clients cross-functional teams. The approach consisted of the following steps

- Generate: each workstream had problem and goal statements, as-is pain-points and roots causes understood.

- Incubate: solutions were designed and tested in live project scenarios.

- Deliver: solutions were then reviewed and refined through retrospectives and embedded into business as usual.

Stage 3- Systemise: With proven prototypes, systemise solutions and empower the team to transform their delivery performance

An operating model was established to utilise the solutions systematically helping to realise and maximise their benefit, enabling the client to save 766 hours per month by the end of the project, compared to the original ways of working. To enable sustainment, handbooks were developed, a knowledge repository was implemented, and the leadership and team members trained in APMG project controls.

Outcomes

By taking an adaptive delivery approach, our team were able to regularly release value to the business at the end of each sprint, opposed to all benefits being realised at the end of the project. This value snowballed across the 12-month duration of the project as the work gathered more momentum.

Some of the outcomes the team delivered included:

- Revised 3-level protype vehicle development project delivery with a Project Management tool implemented and supporting gateway process with 100% adherence achieved.

- Standardised project scheduling capability- implemented on all 7 projects that were live during the engagement.

- Change control process designed and implemented to ensure BoM changes were recorded and recognised by all functions.

- Capacity and demand forecasting, estimating and what-if scenario analysis tooling.

- Risk, assumptions issues, and decisions (RAID) management with over 52 high and critical items identified and mitigated.

- Governance model with 6 forums enhanced or embedded and with improved supporting management information, reporting and communication standards (Portfolio alignment, RAID and strategic management , project kick off and reviews, strategy and process meetings).

- Sustainment measures were implemented through a Project Management Office (PMO) approach and layered audit.

- A central knowledge repository containing PM system components handbooks, accessible by all functions.

Benefits and Lessons Learned

The project was designed to test whether increased PM maturity would benefit the wider client organisation by increasing delivery output against a backdrop of increased technical complexity. It was resultingly viewed an unprecedented success by all areas of the client organisation (including their CEO). Key metrics which MP improved were:

- On-Time-In Full delivery increasing from less than 70% to over 95% sustained for 9 months with highs at 98%.

- This has ensured on time delivery for 7 vehicle projects during the joint engagement, ensuring these vehicle models could be proven as market ready, ready for full scale production.

- 10 figure revenue impact mitigated by regaining control of the programme.

- AMP Project Management Capability score increase from 1.7 to 3.1 with a roadmap for further improvement to 4 being implemented by the client team without the need for external support.

- 700+ hours per project per month saved within the prototyping function alone.

This article was written by James Murray, Industrial Sector Lead.

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.