Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible

The automotive industry is a complex ecosystem involving a global network of suppliers, manufacturers, and distributors. Effective management of an automotive supply chain is crucial to ensure that necessary components are available at the right time. Given the high degree of interdependence between entities in the automotive ecosystem, any disruption can have a significant impact on the entire supply chain. A single missed shipment can lead to a gap in supply for the next tier, resulting in a snowball of expensive expedites and recovery plans.

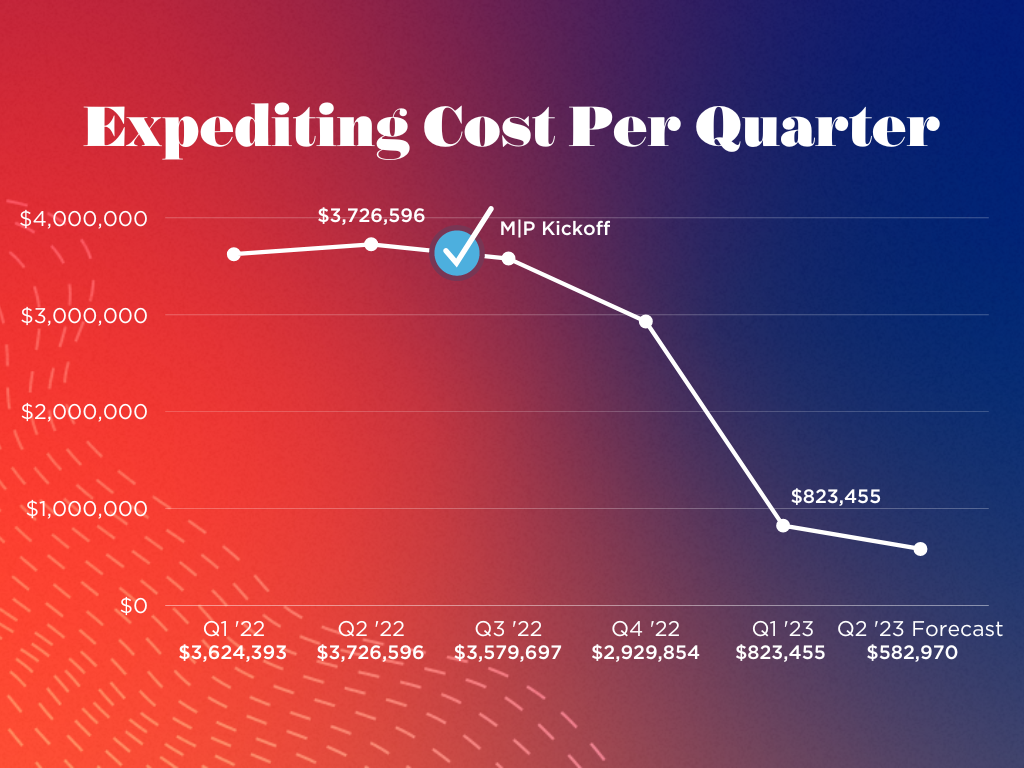

Our client, a leading supplier for major automotive OEMs and tier 1 automotive and aerospace companies, was struggling to anticipate such supply chain disruptions. For over a year, expedited shipment costs exceeded $3 million USD per quarter due to obstacles in their global supply base. The client requested immediate help to stabilize their supply chain, manage their supply base, and standardize their overall planning process.

MP established a Supply Chain PMO to mitigate risk to their operations by providing visibility before an issue occurs.

Before engaging MP, the client completed a supply chain diagnostic to identify the strengths and weaknesses of their current operations.

The MP team reviewed the diagnostic findings and observed that the client lacked standardized processes and visibility, causing continuous supply chain surprises and unforecasted plant downtime. Internally, the supply chain issues were causing bottlenecks and limited planning capabilities, as critical machines would sit idle at times due to a lack of component availability. In just six months, the client was forced to process over 2,000 expedited shipments to meet their customer’s needs, which cost them over $7.4 million USD.

Once engaged, MP found that the client’s supply chain was burdened by multiple issues occurring simultaneously:

The client needed MP’s support to improve their global supply chain operations and mitigate any risk before it affected their production any further.

An MP team composed of project managers and supply chain experts worked closely with the client to establish a Supply Chain Project Management Office (SC PMO). Once the team understood the client’s current and ideal state, they developed a comprehensive roadmap to quickly improve supply chain performance.

The mitigation plan consisted of four key components:

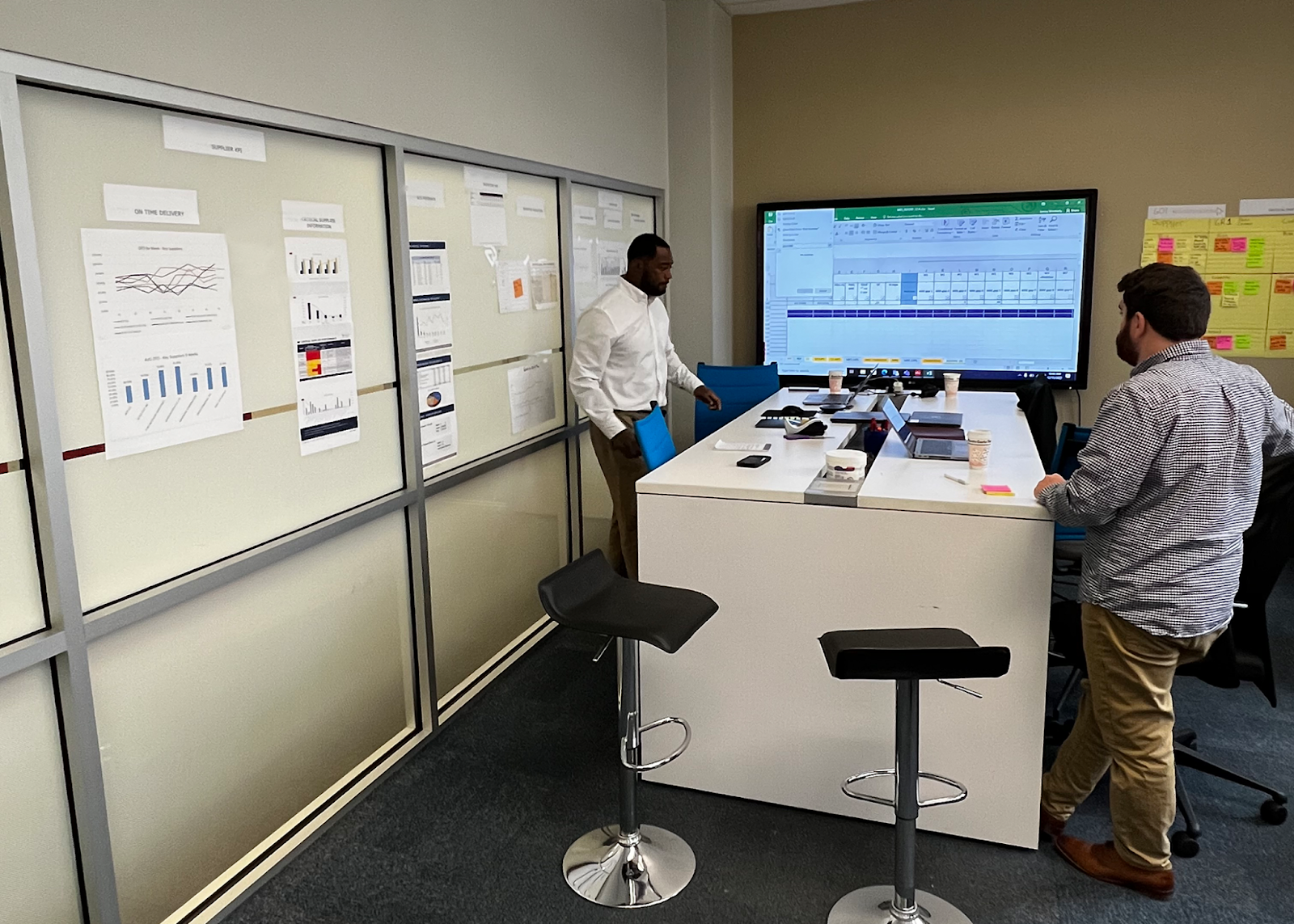

1. Obeya Room Implementation: The client’s top priority was preventing missed shipments to its customers. Organizing an Obeya Room allowed the SC PMO team to visualize and manage all operations related to the client’s supply chain. This visual management strategy helped them quickly and accurately identify and escalate supply chain issues.

2. Standardization of Supplier Management: Once the client’s global best practices of managing suppliers were understood, the MP team integrated them locally to adhere to those standards. Then, the SC PMO implemented two new tools: one to assess current supplier shortages and the other to forecast future stock projections. This streamlined the escalation process to give all teams a clear view of daily and weekly priorities.

3. KPI and Data Management: To improve the efficiency of the supply chain operations, the SC PMO consistently recorded and reported on KPIs (daily, weekly, and monthly). This allowed them to track the operation’s improvements and costs. Utilizing this data enabled the client to be proactive with their resource allocation and future sourcing activities.

4. Risk Mitigation: The SC PMO created and executed a risk management framework that efficiently identified and mitigated risks associated with the supply chain. This included regularly monitoring supplier performance, identifying potential disruptions, and developing contingency plans.

After defining and approving the mitigation plan, the SC PMO worked closely with the client’s operations and procurement teams to implement it. MP provided support as process leaders and as key supplier contacts to ensure that the suppliers’ distributions were being managed effectively. The supplier capacity tracking and recovery plan that the SC PMO executed allowed for more precise production planning.

By implementing daily escalation meetings and weekly reporting through the war room, all stakeholders throughout the supply chain could efficiently see the daily gaps and their effect on production. This visibility drove accountability and action which allowed the management team to focus on strategy and aligning operations to overarching department and company objectives.

By executing and implementing the mitigation plan, the client’s supply chain operations stabilized within one year of partnering with MP. The SC PMO efforts helped the client increase their production to meet their sales targets. This improved the client’s bottom line by reducing costs and driving more revenue. The cost associated with expedited shipping was reduced by over 50% just 6 months after project kickoff, resulting in cost savings of over 2 million USD per quarter.

The supply chain department, which struggled with employee turnover and frequent priority changes, stabilized. Improved internal alignment also clarified team members’ roles and priorities, giving them weekly targets to meet and improving morale, communication, and delivery.

With the supply chain KPIs provided, the client now has a stronger footing in supplier negotiations and can use this data to drive new contract terms or pricing changes. The risk management framework helped the company identify potential disruptions and minimize their associated impact.

After helping the client to control the supply chain crisis, MP is able to support the client with organizational change management, providing supply chain KPI tracking, MRP alignment, and logistics cost analysis.

This article was written by Kyle Bailey and Priyank Patel.

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.

We combine our expertise with a fine knowledge of the industry to deliver high-value project management services.

MIGSO-PCUBED is part of the ALTEN group.

Find us around the world

Australia – Canada – France – Germany – Italy – Mexico – Portugal – Romania – South East Asia – Spain – Switzerland – United Kingdom – United States

© 2024 MIGSO-PCUBED. All rights reserved | Legal information | Privacy Policy | Cookie Settings | Intranet

Choose your language

Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible