Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible

Sellafield is a pioneer for the UK’s nuclear industry and the world’s first commercial nuclear power station to generate electricity on an industrial scale. Today, Sellafield Ltd. runs the largest nuclear decommissioning site in the UK where they are focused on cleaning up the world’s largest inventory of untreated nuclear waste. MIGSO-PCUBED was asked to support Sellafield using Lean Process Improvement Consulting in its transformation into a more efficient, productive and cost-effective organisation.

Read also our industry article: Sustaining Performance with Energy Project Management Services

Watch our case study in video 🡪

MIGSO-PCUBED originally started to work with Sellafield as they underwent a period of significant change. The organisation needed to clean up the legacy of the site’s early operations which involved decommissioning some of the most hazardous nuclear facilities in Europe. At the same time, they were also adopting a new procurement model, which would see them deliver projects with fewer partners over longer periods.

Our mission was to support Sellafield in its transformation into a more efficient, productive and cost-effective organisation prepared for the changes ahead. To do this, we leveraged our own bespoke methodology, “Lean Innovation” across Sellafield Ltd’s Project Delivery Directorate.

Lean Project Delivery is based off our Lean Innovation Framework, which combines Design Thinking, Lean and Scaled Agile into one end-to-end delivery package. It’s a customer and employee focused approach to identify and transform business critical processes, products, and services.

Beyond helping the organisation to get the most benefits from their new procurement model, our objective was to realise process improvements that would deliver enormous savings in time, cost and effort. Lean Innovation was the perfect tool for the job.

“Working with MIGSO-PCUBED has probably been the most powerful alliance we’ve had in a long time”

- Andy Tyson, Head of Project Management Capability

Before we could improve processes, we had to identify where these improvements can be made.

With Sellafield project teams, we identified a backlog of 152 points of improvement and prioritised these against Sellafield’s strategic drivers. What emerged was a group of 9 ‘Opportunity Areas’, or projects that were ripe for improvement.

After identifying areas of improvement, we encouraged Sellafield to envision possible solutions – the sky’s the limit when it comes to ideas. This is a cornerstone of our Design Thinking approach.

What if you could do anything?

The long-term vision of this project was to deliver continuous change which would last long after the project was over. An objective like that calls for empowered champions who are comfortable delivering change. Linked to Change Management methodologies, champions fulfilled the role of ‘Change Agents’ who would continually improve Sellafield without our support.

So with the aforementioned opportunity areas identified, we set out to train a group of people in our methodology. Our approach was to embed these ‘champions’ into each of the nine Opportunity Areas, so that they could carry out the improvements.

30 champions were handpicked by senior sponsors and advanced through an intensive 3 day champion training programme. Training covered the fundamentals of Lean Project Delivery, including key elements from Lean Six Sigma, Agile, Design Thinking, Team Psychology and more.

With the Sellafield champions trained and motivated, it was time to get started on making improvements.

To foster innovation, we held collaborative ‘Improvement Events’ for each of the nine Opportunity Areas. In these events, we brought together a team of key personnel from each of the identified projects along with Lean Project Delivery champions to participate in a focused 3-day workshop.

For each event, a senior sponsor would pose a ‘sponsor’s challenge’. This is the high-level goal of the sponsors and represents the improvements they want to see the team make. The group’s focus is to devise innovative solutions to the sponsor’s challenge along with a clear roadmap of improvements.

Solving the sponsor’s challenge begins with a focused period of defining value. In each of the Opportunity Areas, teams are assembled to map out their current processes in detail (as-is mapping). The beauty of having all the team gathered together is that no part of the processes being mapped out is missed, revealing the areas of waste within a project.

With the processes mapped out, the teams begin a 3-day focused ‘Improvement Event’, or ‘work-out’ where solutions are developed to address the sponsor’s challenge. On the final day of the event, the teams present their solutions to a decision-making panel formed by senior sponsors. The team get on-the-spot approval for their solutions and develop an action plan to put them into effect.

This phase is all about putting solutions into action. We do this within an iterative framework, which emphasizes quick feedback cycles frequently testing the solutions to see which deliver the most value.

In Sellafield, senior sponsors and the MIGSO-PCUBED delivery team gave the participants clear, achievable targets which were assessed in intervals of 30, 60 and 90 days.

These fast-feedback loops gave Sellafield the ability to quickly understand what activities delivered the most value, allowing them to pivot from those that delivered the least.

Our third phase is focused on deploying solutions across an enterprise, empowering teams to transform their own areas of work.

To do this at Sellafield, we made use of the Scaled Agile model. With this, we were able to deploy ready-made improvements across disparate teams, gaining enterprise-wide buy in for the improvement program.

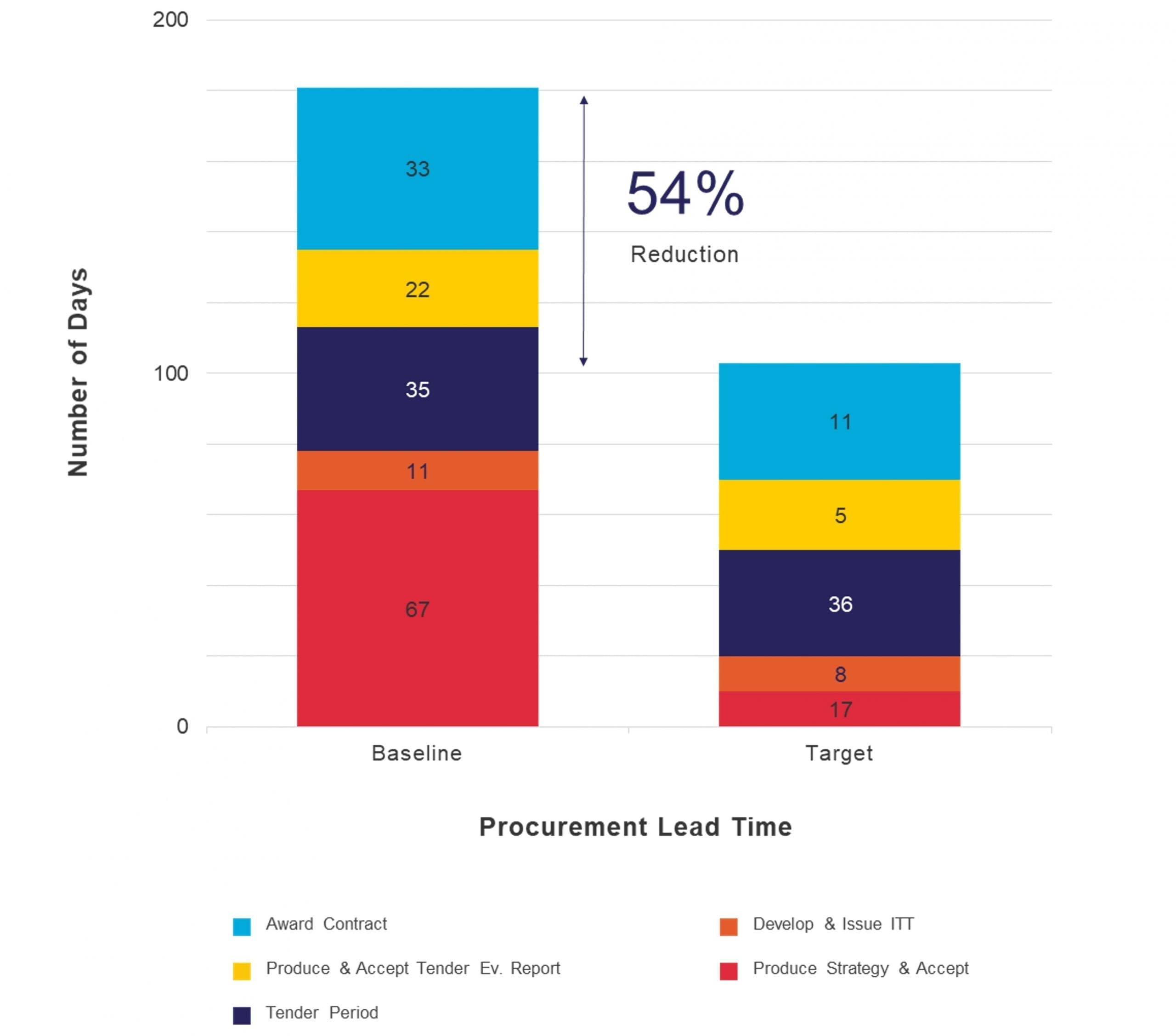

The complexity of processes the Sellafield Procurement team had to manage were causing minor delays. Their processes took longer than expected and contributed to unpredictable lead times in procuring engineered items, construction materials and equipment. With a significant number of packages to procure, the project team needed to make improvements quickly. The team also needed renewed confidence in the repeatability of the process and above all else, a process that ensured schedule dates were met on time.

During an Improvement Event, we identified the cause of the delays: approval reviews were being repeated at multiple stages in the process. We also discovered that variations in carrying out the procurement process made lead time predictions increasingly less accurate.

The team proposed a mandatory collaboration meeting to create and agree the subcontracting procurement strategy. The solution was set out to stop the multiple revisions and reviews happening as a result of several parties producing their strategies in isolation. The team also proposed a mandatory, updated template to remove duplicate requests. Both solutions would save time and avert delays caused by the duplication of effort.

Beyond this, the team agreed to set up an ambitious tender management system. Aside from cutting waste and the associated cost in time and money, this system also increases the pool of options for suppliers. This new, streamlined process freed from the disincentives associated with contracting new suppliers will allow the procurement team to pursue excellence over convenience. No longer bound by a process that punishes new competition, this project will pay dividends in cost and performance.

By simplifying the process, the team identified the means to save ten months in project time. In addition, the team was able to increase the number of packages procured by 90%, monthly contract awards by 90% and reduce the forecasted lead time of procurement by 33%.

As you can see from the image below, we were able to drive huge improvements across the board, in many cases surpassing the team’s targets.

It’s difficult to sum up the benefits of a wide-ranging process improvement project that spanned nine Opportunity Areas within Sellafield Ltd, so here are the headlines from just two of the areas we helped to improve:

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.

We combine our expertise with a fine knowledge of the industry to deliver high-value project management services.

MIGSO-PCUBED is part of the ALTEN group.

Find us around the world

Australia – Canada – France – Germany – Italy – Mexico – Portugal – Romania – South East Asia – Spain – Switzerland – United Kingdom – United States

© 2024 MIGSO-PCUBED. All rights reserved | Legal information | Privacy Policy | Cookie Settings | Intranet

Choose your language

Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible