Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible

How MIGSO-PCUBED is helping this leading automotive company transform their business.

Few mass-produced products are as complex as a car. Designing and manufacturing a new car takes the effort of hundreds of people, dozens of processes and a multitude of data. Getting all participants to use the same technology platform to maintain the information about their work can go a long way in improving collaboration, productivity and efficiency. It’s also an ambitious undertaking.

Yet that’s exactly what the PSA Group aspires to do. For the last two years this European car company has been putting in place a new Product Lifecycle Management (PLM) application. When it’s done, the new IT system will drive change throughout the organization to improve processes from design through manufacturing.

The organization faced the same challenges that beset other global manufacturers: Information was compartmentalized; everybody used their own preferred tools; and the software portfolio was “bloated,” full of applications that were duplicative or under-used. As a result, information resided in siloes, making decision-making overly time-consuming.

However, in the automotive segment, those problems are intensified because of the sheer pace and growing complexity of building innovative cars, which are packed with all kinds of new technology.

By adopting PLM the company aims to embrace a single approach and tool for managing the work of designing, developing and validating all components used in its manufacture of new vehicles.

In 2011, the PSA Group initiated the “Drive” program, intended to address PLM across global operations. The primary goals of Drive: to accelerate performance gains in its extensive research and development efforts and improve collaboration with its suppliers and alliances. The basic idea of PLM is to have everybody work in the same software program to enable the data they generate (specifications, designs, feedback, etc.) to be accessible and shareable by users. The PLM program would maintain information integrity and become the “single source of truth.”

After 2 years of hard work, we have a complete portfolio of tools including documents, processes, workbooks, indicators and dashboards in order to help end-users to utilize the PLM application on their project. Today, we are now in front of new challenges: to generalize the PLM use on all new projects and to widen the use perimeter of PLM. Our target now is to engage new departments of the company, including functional and testing teams, as well as manufacturing teams. We are sure that our partner, MIGSO-PCUBED, will be able to provide additional skilled team members in order to succeed in this new challenge.

Bruno Goujon - PLM Support Manager

The technology solution the group chose as the Drive platform was Dassault Systemes Enovia. Enovia provides functionality in several areas: Product planning and program management; Product development; Quality and compliance; Intellectual property protection; Supplier management; Customer requirement management.

The software allows everyone on the project to use specific functionality to do their work, based on their access rights and responsibilities. Then that data can be consolidated for reporting purposes.

The PSA Group was already using other Dassault programs, such as CATiA, for its product design work, which would integrate with Enovia. But the company also recognized that Drive would require big changes in the processes used across the board in all of the departments involved in product development. For that reason in 2014 it brought in MIGSO-PCUBED to help with change management for its pilot projects, where it would test out the new software before rolling it out more fully. Eventually, the role of MIGSO-PCUBED grew to encompass other phases of the project: operational deployment, validation and specification.

Drive would employ two important elements. The first was an engineering handbook that would standardize all design processes and provide a global and structured vision for designing and managing activities and would cover all product lifecycle stages. In other words, the handbook would contain all of the processes used to do the work.

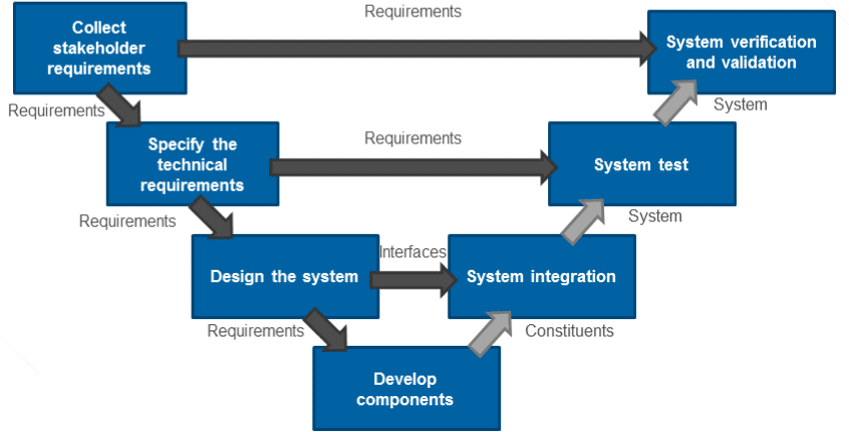

The second element was the use of the “V-cycle.” Whereas the PLM is the tool to be used, the V-cycle is an approach that defines how new products would be developed, so-named because of the shape the activities followed. The V-cycle starts with collection of stakeholder requirements, moves through specification of technical requirements and so on, all the way through system verification and validation.

Getting employees to adopt these new elements was the initial focus for the MIGSO-PCUBED team. It’s a human tendency to resist change, but the PSA Group also wanted to make sure employees really understood why the change was important, how it would affect them, and to what extent they needed to get involved in the pilot efforts.

MIGSO-PCUBED set up a five-stage strategy to encourage people to shift from skepticism to enthusiasm.

In order to improve its practices within the PSA Group, the MIGSO-PCUBED team follows two rules:

First, the team works in a dedicated room where it can maintain its whiteboard thinking, flowcharts and other activities without having to recreate that information continually in new locations.

Second, the team practices a short, effective “ritual”: It meets in that room once a week to examine the work done, the work coming, and potential areas for improvement. “Reflecting on our work ensures that we are continually improving our own processes alongside our clients’ efforts to do the same.”

Operational deployment consists of two broad activities:

As the MIGSO-PCUBED team began monitoring the deployment project, they found that the schedule wasn’t being adhered to for delivery of new functionality within the PLM. Or it arrived missing aspects that were part of the specifications. As project managers, the team knew there had to be a better way.

The PSA Group has been a long-time user of Planisware project portfolio management (PPM) software, a high-end application for managing schedules and resources for major product development. So MIGSO-PCUBED began using that to stay on top of variances in the schedule for the pilot project. They also built a “quality” grid and performance dashboard that enables us to oversee the quality of the PLM deliverables as they’re developed.

The use of those tools provides the group’s decision-makers with visibility into project status and gives them the information they need for making go/no-go decisions. They also give executives an overall feel for the progress and level of risk on a given design project. For example, one dashboard component communicates the “mass” or weight of a given major component. As additional “virtual” parts are added to the design of the powertrain, that weight goes up, a change reflected in the dashboard. While a piston indicator may be red today, several months from now, as the gearbox is more fully developed, it will be green; they can understand that by doing a drilldown on the data through the dashboard.

The PLM project isn’t over, and the change will continue for several years. But even now this multi-million Euro investment is already showing value to the company. With every user brought into the PLM fold, collaboration is steadily improving; decision-making is becoming stronger; and R&D is truly accelerating the gains it can make in its work related to car design. On the pilot projects, the quality, cost and delay (QCD) impacts of design changes are always automatically updated with the latest information. For example, when there is a modification in a technical solution, the weight of the new component is calculated in the PLM and the “Weight Pilot” can access the information and share it with customers without having to update a lot of different databases.

MIGSO-PCUBED consultants have brought expertise in project management, knowledge of the automotive industry, talent in managing issues more effectively, and an ability to listen to stakeholders and come up with approaches for addressing their concerns while still keeping the project moving forward.

3 brands: Peugeot, Citroën and DS

2nd European vehicle manufacturer

2015 sales: + 2.9 million vehicles worldwide

2015 Revenue: €53.6 billion

Employees: + 184,000 worldwide

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.

We combine our expertise with a fine knowledge of the industry to deliver high-value project management services.

MIGSO-PCUBED is part of the ALTEN group.

Find us around the world

Australia – Canada – France – Germany – Italy – Mexico – Portugal – Romania – South East Asia – Spain – Switzerland – United Kingdom – United States

© 2024 MIGSO-PCUBED. All rights reserved | Legal information | Privacy Policy | Cookie Settings | Intranet

Choose your language

Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible