Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible

Our client, a leading Automotive OEM, was on a journey to improve its global product development framework currently in use by more than 60,000 of its employees. They had reached their tipping point, and in order to stay competitive, they needed a faster and more cost-effective approach to develop and deploy global products.

MIGSO-PCUBED, a long-time partner, had previously implemented Project Management Offices within the OEM. The PMOs were designed to help automotive program management teams deliver quality product launches on time and in a more organized fashion. The MP team quickly ramped up to help manage the redesign and rollout of their new product development process.

Our client needed to drive continuous improvement to both the processes and tools utilized within their Product Development Framework. Without a globally-centralized Enterprise PMO, the customer was struggling to coordinate, plan, and execute the suite of changes against their portfolio of programs.

Furthermore, delivering an updated system involves complex logic checks to ensure that both upstream and downstream impacts of any proposed changes are fully understood by the engineering and manufacturing communities. Due to the tight connection between process and tools, both needed substantial support to ensure successful releases, mitigate potential risks, and support large-scale training and communications.

A global Transformation PMO was therefore established to manage the portfolio of unique but connected programs and projects. MP resourced the enterprise level PMO by providing on-the-ground support in key regions.

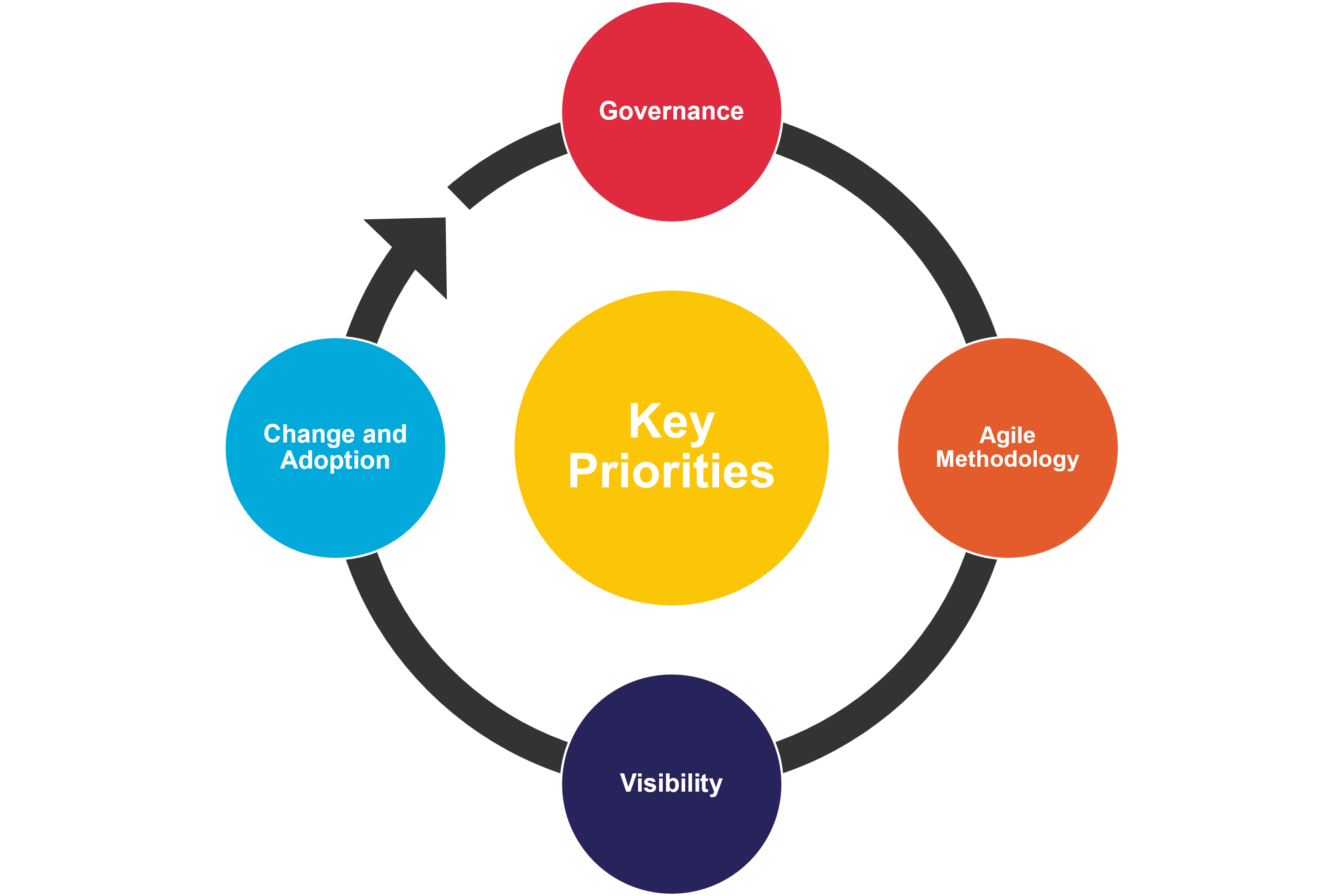

Key emphasis was placed on:

To learn more about the different types of PMOs, read our PMO Guide.

Redesigning a Global Framework utilized across multiple regions, functions, and vehicle platforms is a rather complex endeavor. To help address the many issues and challenges faced, the MIGSO-PCUBED PMO recommended dividing the transformation portfolio into four key areas:

One of the key goals of the process redesign was to improve time to market. That meant the realignment of existing timelines and programs to meet competitive timing targets.

The first step required was to implement a strong governance structure. This ensured that each vehicle program following the redesigned process would begin on time and that everyone involved understood the requirements and their roles.

A Governance workstream team within the PMO supported the inflight vehicle teams, ensuring that everyone understood the new timeline, specific constraints facing the project, and how to use associated tools. To ensure projects stayed on course, timing templates that outlined the key phases from beginning to end were created and shared throughout the organization.

The next hurdle was then to create a Portfolio Roadmap – a timeline for each of the projects within the portfolio of vehicle program launches that would be impacted by any proposed process changes. In theory, based on which milestone a vehicle program had progressed through identified whether it could be a candidate for a proposed process lifecycle change. The team then had a Portfolio Roadmap baseline by which to flex changes in vehicle program timing and process or tool solution availability.

The second workstream within the PMO was focused on delivering ongoing process and tool enhancements using an Agile framework. With changes affecting over 60,000 employees over more than 100+ in-process programs, incremental changes were rolled out to individual teams and tested before program-wide adaptations were implemented.

To ensure quality and consistency across program teams, the team established and published project-specific guidelines as a uniform standard to simplify the process and avoid redundancies. Tool-based iterations (sprints) were mapped out into two-week durations. The iterations followed a detailed review process by multiple levels of the team and management to ensure deadlines and requirements were met. This allowed them to define a framework that enabled fast feedback from the team, and updates to tools that improved engineer efficiency, productivity, and quality.

Within these guidelines, MIGSO-PCUBED created robust program development plan templates and Micro Program Timing Tools. This assured that the team had easy access to the tools they needed and the proper training to complete each iteration. Opportunities to leverage various tools were constantly investigated to improve usability and efficiency.

Lastly, with iteration timelines mapped out for the lifecycle of the project, frequent changes to deliverables were expected. Change impacts to the program were frequently analyzed and addressed, coupled with updated training to support these changes.

As the PMO had implemented Agile methods to enhance their speed in rolling out process changes, so too had the Engineering department implemented Agile in their vehicle software development methods. Pockets of the organization had already adopted tools like JIRA and Azure DevOps. The PMO assisted these engineering communities with the implementation of a PPM tool helpdesk and ongoing end-user training, ensuring adoption, as well as accurate program status, was reflected in the suite of tools.

Read Also: Advanced PMO Setup

The third workstream within the Transformation PMO was around improving the visibility of program status and risks to delivery. Design issues delaying launch could derail any enhancements gained through process changes. Focusing on improving visibility allowed management teams to have the right data to make decisions, resolving concerns before it’s too late or too costly.

In order to provide Program teams with an accurate status of their progress, the PMO workstream team developed a Global Product Development Dashboard. This dashboard utilized Qlikview and pulled in data from over 30 unique data sources. It included critical KPIs for Program Health and summarized the high risks impacting production within the designing and manufacturing process. The dashboard provided a single source of truth for program teams to obtain an accurate assessment of their program delivery risks and issues.

The team identified thresholds for critical KPIs serving as early warning indicators, as well as completed regular analysis on how to improve vehicle program time-to-market. The dashboard now provided predictive analytics that allowed the OEM to predict the downstream effects of upstream changes and constantly showed the program’s health. By creating and supporting the ongoing maintenance of a digital KPI dashboard, the team increased program status visibility and drove more effective and efficient program reviews.

The MIGSO-PCUBED PMO team showcased the benefit of dashboards. After creating this dashboard, the team identified opportunities to implement additional dashboards highlighting recall issues to reduce downstream complications. The application of this dashboard provided a centralized location for all metrics of the products that faced recalling issues.

Finally, to ensure the organization was well-equipped and apprised of the frequent changes occurring to the Product Development Framework, MIGSO-PCUBED developed a communications program consisting of onboarding program teams to the updated processes/tools, awareness of key changes, and creating and managing training content. The team found that changes were not always well accepted, even when based on requested features or deliverables.

The team needed to keep the more than 60,000 employees who used the system abreast of the new features being rolled out and any associated changes, without overwhelming them, requiring a multi-layered and multi-regional approach to stakeholder communications.

This included:

More than 20 training videos were created and continuously updated to cover applicable topics relating to engineering, marketing, and finance, and lessons learned. By implementing this training multi-faceted training approach, the MIGSO-PCUBED team was able to adequately support the level of change involved as well as positively influence the impact of change felt across each program and region.

Providing access to training helped ease the transition and provided immediate support for the team.

MIGSO-PCUBED brought a mixture of the right skill set of people, agile principles, and practices adopted from the Scaled Agile Framework. This solution simplified the ongoing operations of the PMO and improved the overall product development process. Furthermore, the project consistently met deadlines, budget constraints, and go-to-market deadlines.

The client’s successful adoption and delivery of the Global Product Development system continues to enable their success for the future of the automotive industry and allows them to stay ahead of the market. We are excited to continue supporting them along this journey.

The feedback from the management team following the project further represented their satisfaction with the project.

“I can trust the people that [MIGSO-PCUBED] hires to do what is best for our company and to meet our goals,” said one member of the OEM’s management team. “[MP] gives us the autonomy we need and always comes in with the direct solution.”

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.

We combine our expertise with a fine knowledge of the industry to deliver high-value project management services.

MIGSO-PCUBED is part of the ALTEN group.

Find us around the world

Australia – Canada – France – Germany – Italy – Mexico – Portugal – Romania – South East Asia – Spain – Switzerland – United Kingdom – United States

© 2024 MIGSO-PCUBED. All rights reserved | Legal information | Privacy Policy | Cookie Settings | Intranet

Choose your language

Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible