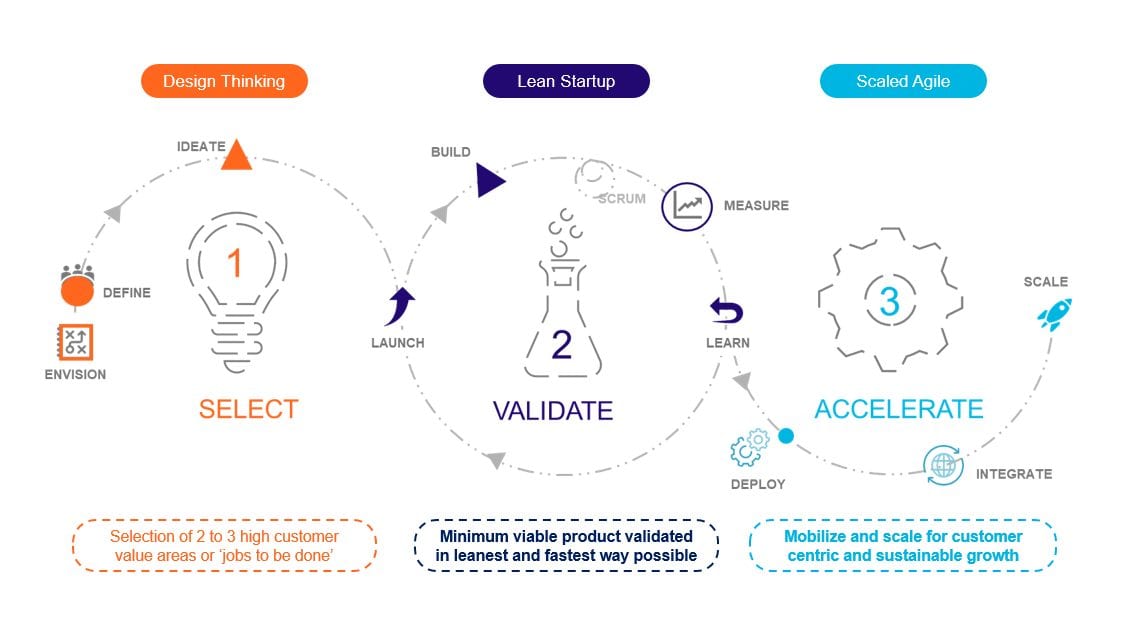

Our client, a leading Automotive OEM, was looking to accelerate innovation by incorporating ‘new ways of working’ into their traditional product development process. MIGSO-PCUBED designed and implemented a Lean Innovation Framework blending design thinking, lean-start up and scaled agile approaches. This enabled them to accelerate the ideation and delivery of ‘minimum viable products’ from 24 months down to 12 weeks.

To kick-off the 10 week engagement, our MIGSO-PCUBED team met with senior stakeholders. Their objective – to understand the goals, objectives and strategic direction for the organization. The team then defined key processes and deliverables required to support the implementation of the new process. The outcome of the first sprint – a tailored Innovation Framework supporting their forward vision.

During the next sprint, the team conducted innovation workshops and engagement ceremonies with both senior stakeholders and associates. While the focus was on creating ideas for future implementation, the team also provided ideas and feedback on the innovation framework itself.

Four client focused workshops were held resulting in over 230 ideas. The team then documented and prioritized them to determine a top 6 for progression. While the Innovation Framework recommends the selection of 2 or 3 high customer value areas or “jobs to be done” – the teams selected 6 High Priority Solutions to move on to the next phase. This allowed each team to follow one high priority solution as they continued on their learning path.

For the next sprint, MIGSO-PCUBED facilitated business model and value proposition canvas sessions to dig deeper into the viability of each of the top 6 initiatives. Following that, it was time to get out of the building and get a better understanding of the customers’ actual wants and needs.

Over a few short days, the teams conducted over 40 user feedback sessions, mapping the customer journey onto a canvas on the wall. Luckily, the viability of their 6 High Priority Solutions were confirmed by the customer. The team was now ready to move into the Lean Startup Phase and launch the building of a prototype for evaluation.

Over the course of the next two sprints, the team continued on their learning journey for newer ways of working. They continued to progress through the lean startup method of Build, Measure, Learn, identifying and testing out their hypothesis as they built their first Minimum Viable Product (MVP).

Our client’s first foray into the Innovation Framework was a resounding success. The team deployed a new process, identified many viable opportunities for advancement into adjacent markets. Bonus result was that they had a great time while doing it.

Key new tools utilized by the teams included: Customer Journey Canvas, Business Model Canvas, Value Proposition Canvas, Learning Hypothesis, Test Case Backlog and MethodGrid.

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.

We combine our expertise with a fine knowledge of the industry to deliver high-value project management services.

MIGSO-PCUBED is part of the ALTEN group.

Find us around the world

Australia – Canada – France – Germany – Italy – Mexico – Portugal – Romania – South East Asia – Spain – Switzerland – United Kingdom – United States

© 2024 MIGSO-PCUBED. All rights reserved | Legal information | Privacy Policy | Cookie Settings | Intranet

Perfect jobs also result from great environments : the team, its culture and energy.

So tell us more about you : who you are, your project, your ambitions,

and let’s find your next step together.

Dear candidates, please note that you will only be contacted via email from the following domain: migso-pcubed.com. Please remain vigilant and ensure that you interact exclusively with our official websites. The MIGSO-PCUBED Team

Choose your language

A monthly digest of our best articles on all things Project Management.

Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible