Our Government client started their cost saving journey back in 2016, but by 2020 they were losing momentum. New ideas were being hindered by the COVID-19 lockdown when more than 75% of employees didn’t have the technology to work productively from home. Using our Lean Innovation methodology, we began a small pilot within the Procurement Department to build a roadmap of incremental improvements to unlock efficiencies in their pipeline.

A portion of this case study was published on Civil Service World, read it here.

A HM Government Procurement Department is leading the way in unlocking the potential of their own teams to improve their services and make savings.

The Department had a Spending Review 2015 (SR15) efficiency savings target but, having started the cost saving journey in 2016, they were losing momentum in 2020. New ideas were also hindered by the COVID-19 lockdown when most of the department were unable to visit the office. Less than 25% of employees initially had the technology to work productively from home.

It was clear that new impetus and new ideas were required. FY20/21 was the last chance to close the £1.0m gap to the £5.0m SR15 efficiencies target and COVID-19 did actually allow department team members some additional thinking time.

The client knew that hidden within their corporate services teams was huge potential that would enable them to work more efficiently, effectively, and smarter. Using management consultants was one possible way of gaining new methods to unlock the efficiencies pipeline. However, there were some concerns:

A small team of MIGSO-PCUBED consultants were already working within the Procurement Department on a wider business transformation challenge, and had tabled a number of improvement ideas. The Department agreed to a proposal to begin a small pilot led by the same team on the mutual understanding that the work would provide the Department with a taster of what it could be like if they made the improvements themselves.

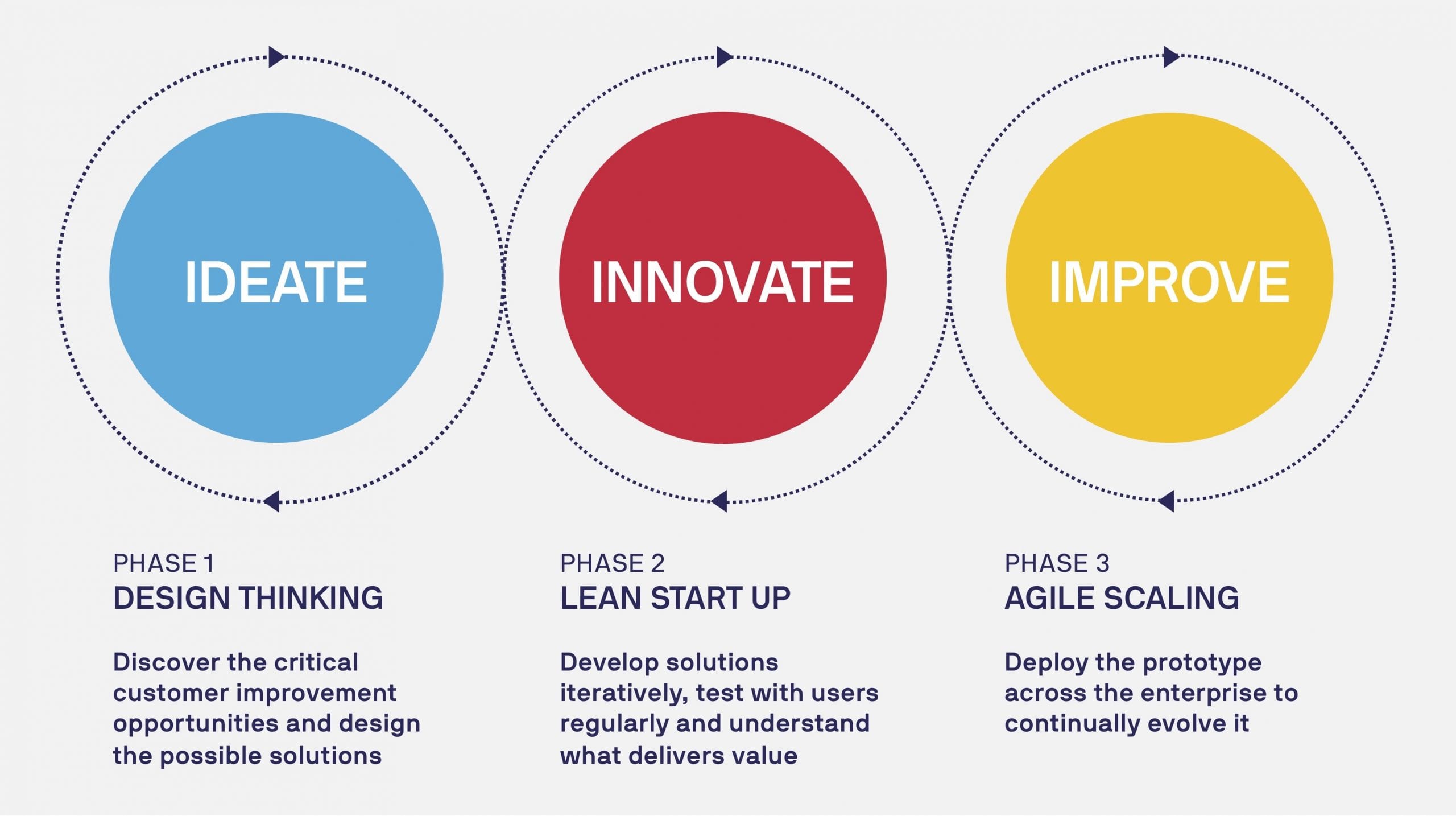

We applied our unique Lean Innovation methodology. Lean Innovation focuses on identifying process improvements within projects which can translate to savings in time, cost, and effort. The methodology blends three proven business improvement disciplines; Design Thinking, Lean Start-up and Agile at Scale.

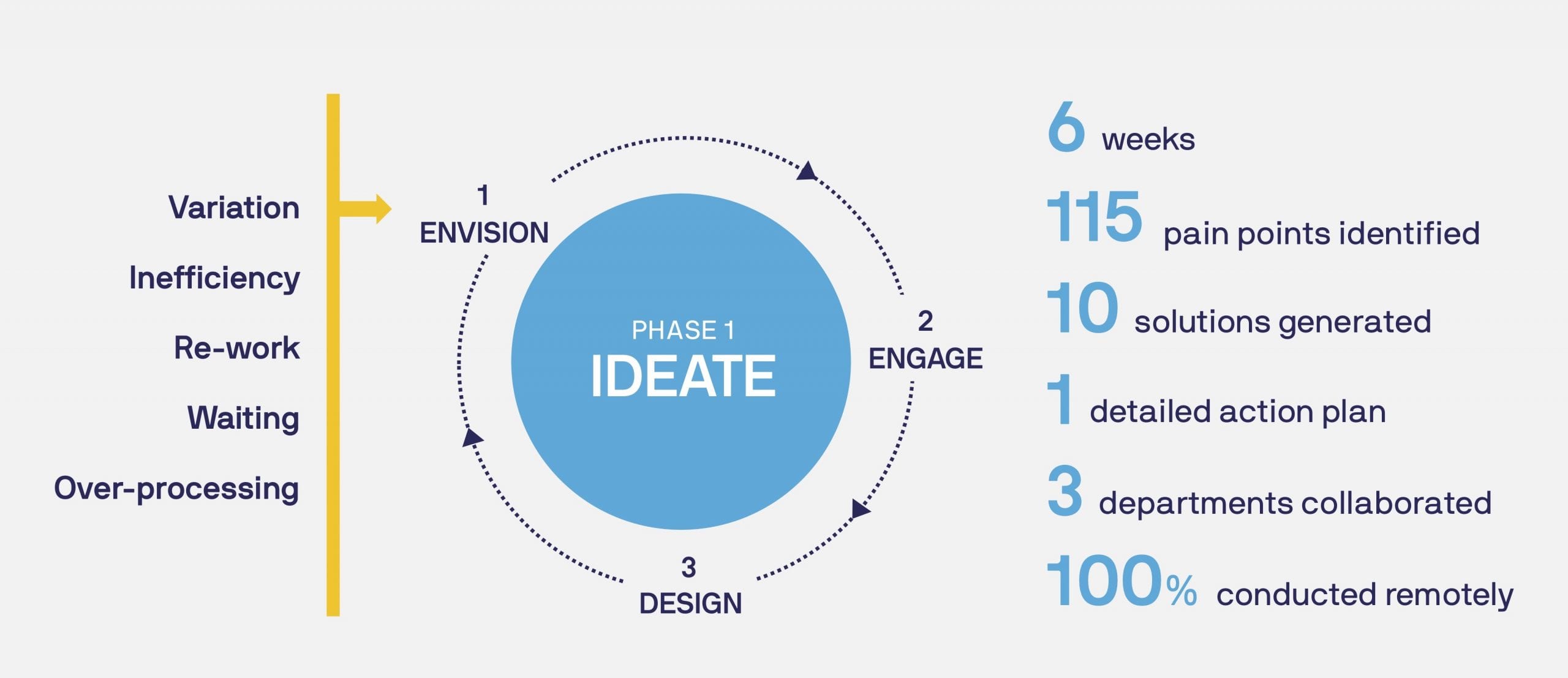

The pilot focused on Phase 1 of the methodology, and a series of collaborative ‘voice of the team’ workshops quickly established a list of areas where improvements could be made. Three departments were involved in the process and 115 unique ‘pain points’, areas of inefficiency or pain in the process, were identified. Departmental leadership ranked and prioritised these pain points to identify the first area to start making improvements.

Read more on how we utilised Lean Process Improvement consulting services to reduce end-to-end process time by 63% in our case study: Delivering Value for a Rapidly Changing Business.

At first it was difficult. During the early workshops, the only common platform available to the team was a telephone conferencing facility. This highlighted what could be done on the phone and what couldn’t.

We’ve done many workshops face to face in an office, but this was a very different matter doing it remotely. Participants hadn’t yet familiarised themselves with online collaboration tools; we learned a lot from working with the department in this way.

The facilitation approach had to develop. Thomson recalled, “Normally putting someone on the spot to make a contribution isn’t encouraged. However, on a telephone call where we are sharing visuals and not faces, it’s needed to avoid people talking over each other or not being able to contribute.”

Other collaboration platforms were forthcoming, but the methodology’s essence is all team members having a voice to put forward their efficiency ideas.

The pilot proceeded to analyse the root cause of issues and to get started on making some improvements. During a collaborative workshop, we encouraged the team to envision possible design solutions. From the 115 pain points, 10 solutions were identified. The solutions were presented at a virtual decision-making panel where the departmental leadership were walked through the problem-solving logic and the solutions with a clear roadmap of improvements. The team got on-the-spot approval for their solutions from leadership with a clear plan of putting them into action.

A key part of the Lean Innovation approach is that team capability is built at the same time as improvements are delivered. Champions fulfil the role of ‘Change Agents’ who take the initiative in developing future improvements – using a ‘participate in one, support one, lead one’ approach.

We taught small groups of Champions their Lean Innovation methodology. The departmental team found the approach easy to pick up.

This has been absolutely fantastic. Logical and structured, made it easy to follow from start to finish.

Collaborating again, amid various lockdowns, became a benefit itself. This has allowed our staff to do value-add work during lockdown, achieving so much in such little time. Exactly what the business is looking for.

The results of the pilot were well received. The solutions made the studied processes quicker and reduced the effort to manage spend. A key benefit was that people became involved and engaged with the business after a while in lockdown.

Even though it was exhausting being online for the 2 - 3 hour workshops, I really felt I was part of the team again, having felt quite isolated during lockdown.

The next cycle of improvement projects is in progress and Lean Innovation looks to become a favoured approach in the department. Thomson said, “Once the Champions have gone through 3 Lean Improvement projects with their teams they reach self-sufficiency in their ability to improve”. The Procurement Department is forecasting that between £0.5m and £1.5m of new efficiencies will be approved from the pilot workshops.

Sellafield started the same journey two years earlier on their 20 year/£100Bn+ decommissioning programme with a portfolio of 9 improvement projects. Although on a larger scale, the same principles applied of using highly engaged teams and the Lean Innovation approach to drive out efficiencies and improvements. Sellafield also developed a centre of excellence in business improvement, staffed by employees trained as Lean Innovation practitioners. Using two major projects in the programme as a first step, results to date include a 50% reduction in procurement lead time with subsequent multi-million-pound savings in overall project cost. As leaders of the programme have said, the improvements amount to a real transformation in their ability to deliver.

Read the full case study here: Sellafield Lean Project Delivery

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.

We combine our expertise with a fine knowledge of the industry to deliver high-value project management services.

MIGSO-PCUBED is part of the ALTEN group.

Find us around the world

Australia – Canada – France – Germany – Italy – Mexico – Portugal – Romania – South East Asia – Spain – Switzerland – United Kingdom – United States

© 2024 MIGSO-PCUBED. All rights reserved | Legal information | Privacy Policy | Cookie Settings | Intranet

Perfect jobs also result from great environments : the team, its culture and energy.

So tell us more about you : who you are, your project, your ambitions,

and let’s find your next step together.

Dear candidates, please note that you will only be contacted via email from the following domain: migso-pcubed.com. Please remain vigilant and ensure that you interact exclusively with our official websites. The MIGSO-PCUBED Team

Choose your language

A monthly digest of our best articles on all things Project Management.

Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible